-

GUARANTEE YOUR HARVESTING

HARVESTING

-

HARVESTING

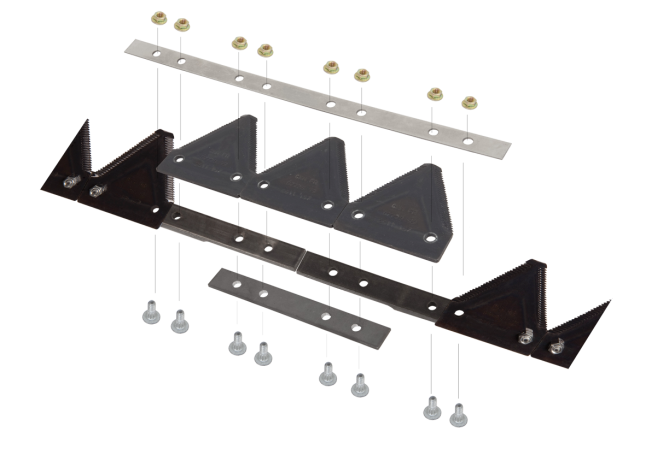

NEW SEGMENTED KNIVES

- The maintenance parts such as knife section, bolt, nut, knife head are all New Holland components already in existence.

- New components are only for the connection system of the knife segments: one connection bar, one top re-enforcement plate and flanged nuts.

They can be ordered within a kit:

• Kit 84519635 with standard sections

• Kit 47641531 with green sections

All details in NGPC in the grain header catalogues.

To guarantee best peformance and durability of your cutter bar, section knives must be associated with Original New Holland guards.

-

ONLY NEW HOLLAND GENUINE BELTS CAN GUARANTEE YOUR MACHINE’S ORIGINAL PERFORMANCE!

BELTS

-

BELTS

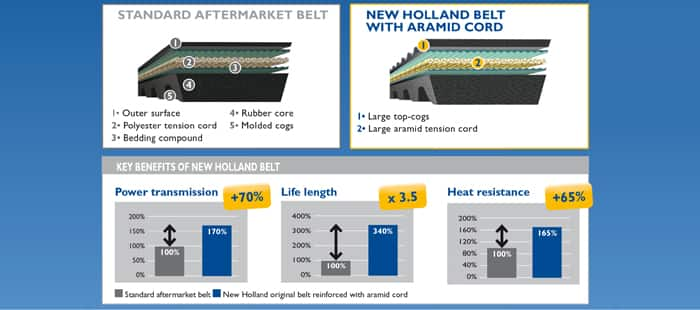

New Holland original belts are superior to standard belts supplied on the aftermarket. Our belts are specially designed by our engineering, to meet the standards of each machine type.

We rigorously select our suppliers and only work with the market leaders, selected for their advanced technology and the quality of the material used.

New Holland original belts are specially developed for heavy duty drives on farming machinery. They are robust and reinforced, composed of materials that are both very fl exible and resistant, specifi c elastomeric compounds and highly resistant cover bands.

V-BELT

Our V-belts are particularly suited for highly stressed drives.

Comparison New Holland versus standard aftermarket belt

VARIABLE SPEED BELT

Further increases in demand on the performance of drive elements led to the development of our double-cogged, variable speed belts.

Comparison New Holland versus standard aftermarket belt

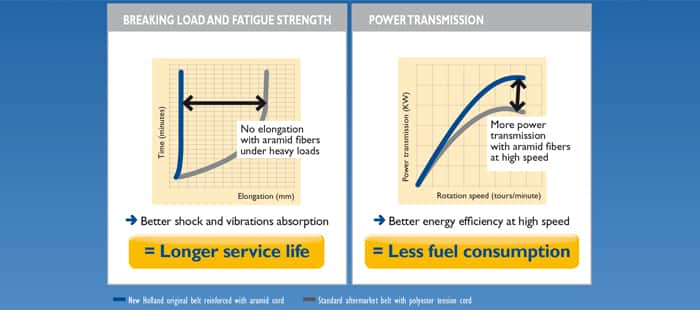

ARAMID FIBERS = SUPERIOR TECHNOLOGY

New Holland high performance belts are reinforced with a special rubber compound integrating aramid fibers.

Aramid fibers are a class of heat-resistant and strong synthetic fibers.

Those fibers optimize power transmission without provoking elongation.

-

PROTECT YOUR ENGINE ENABLING IT TO LAST LONGER AND OPTIMISE ITS PERFORMANCE.

FILTERS

-

FILTERS

The New Holland air filters have been specifically designed for each engine.

- The air filter has a key role to play, it lets through air in sufficient quantity and clears away impurities.

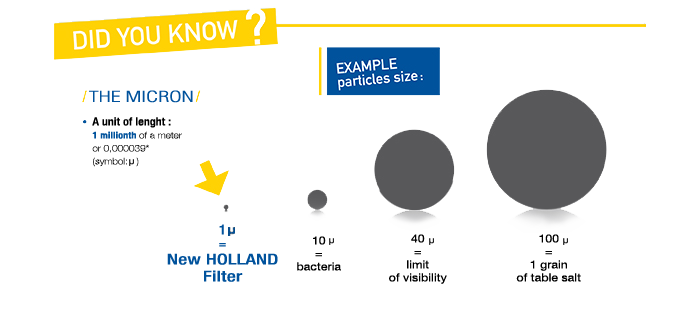

- Providing extremely good performance, trapping dust particles as small as 1 micron.

- After passing through the filter, 99.96% of airborne particles have been removed.

- The risk of abrasion and damage to the engine is therefore minimised and combustion takes place under the best possible conditions.

WHEN SHOULD I CHANGE MY FILTER?It is advisable to change the filter every

600 hours or once a year * (whichever arises first).

A saturated filter reduces the intake of air, reduces engine power and increases fuel consumption. It is therefore essential to replace it regularly.

* Please refer to the maintenance logbook for your vehicle, or to the notice on the filter for more information.

-

NEW HOLLAND ROTATING BEACONS FEATURE ALL THE CHARACTERISTICS OF A PRODUCT DESIGNED TO LAST

BEACONS

-

BEACONS

TEST 1: RESISTANCE TEST

Shock resistance, unbreakable domes

The polycarbonate dome means the NEW HOLLAND rotating beacon dome is virtually unbreakable. Unbranded replacement domes, often made out of polymethacrylate, break frequently, and are not very durable.

TEST 2: LIGHT INTENSITY TEST

Light intensity: + 30 %

The NEW HOLLAND rotating beacon comprises a rotary unit featuring technology which ensures optimum distribution of the light beam. Tests show that NEW HOLLAND rotating beacons give out 30 % more light than required by European standards.

TEST 3: WEATHERPROOF TEST

Optimum protection against dust and humidity

The high protection rating (on average 55) of NEW HOLLAND rotating beacons offers excellent weatherproofing against external elements including dust and water.

New Holland beacons are homologated according to regulation n°65 ECE/ONU.

This guarantees that the beacon fully meets the value of effective candela (unit measuring light emission).

NEW HOLLAND beacons = + 30% additional luminosity vs European standards

-

IN THE DARKNESS, MORE POWER TO THE LIGHT

LAMPS

-

LAMPS

The key benefits of LED lighting are:

- Reduced power consumption - reduces consumption by 50% compared to Halogen.

- The ability to match the level of light to the application (greater choice).

- Long life span, LED lighting is designed to last the life of the machine (no upkeep costs).

- Increased colour temperature: reduced eye strain.

- Vibration dampened to survive harsher working enviroments.

New Holland LED Working Lamps:

- IP69K: sealed from water ingress.

- Reverse polarity and over voltage protected: the lights will not suffer damage from voltage spikes or other fluctuations in current.

- Designed to work in temperatures -40 to +75°C and include thermal sensors to prevent heat damage to the LED’s.

- EMI/EMC suppression: the working lamp is designed to Class 5 of EN55025, in it simplest form this means the emissions from our lighting will not interfere with other electronics on your machines.

- Light output - measured in lumens. All LED lights have a reduction in output from cold start up to steady running. The better designed the product the smaller this drop will be. In some cases this can be as much as 50%

-

TRUST WHO REALLY KNOWS YOUR MACHINE: ORIGINAL GLASS FITTED BY QUALIFIED TECHNICIANS ENSURE YOU ARE WORKING IN THE SAFEST CONDITIONS

GLASS

-

GLASS

Thanks to Original products, you can work in total safety:

- Our windshields are certified

- Our quality products are tested by our engineers

- Glass designed and built for your New Holland vehicle which is guaranteed to fit perfectly first time, every time

Most of our glass products are “toughened”, which means that they are heated to between 570°C and 700°C, and then the surface is quickly cooled.

Toughened glass is five times stronger than normal glass!

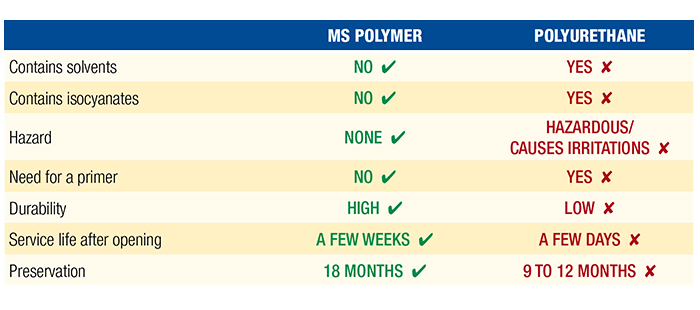

When toughened glass breaks, it separates into numerous blunt parts, thereby guaranteeing optimal safety.Our range of adhesives is MS polymer-based. This type of technology offers numerous advantages over polyurethane-based technology.

-

LONGER LASTING WINDSCREEN WIPERS

WIPERS

-

WIPERS

Because your agricultural vehicle is your working tool it must be at peak performance throughout the seasons.

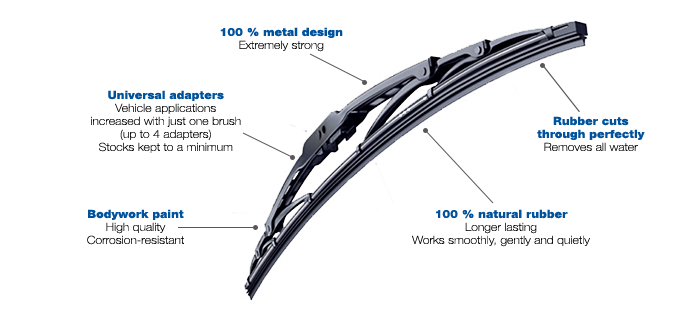

The new range of New Holland windscreen wipers, made in Europe, fully meet your long-term quality and reliability requirements.

Front, rear or side windscreen wipers, your windows must be completely transparent to save time, to be safer and to make working easier.

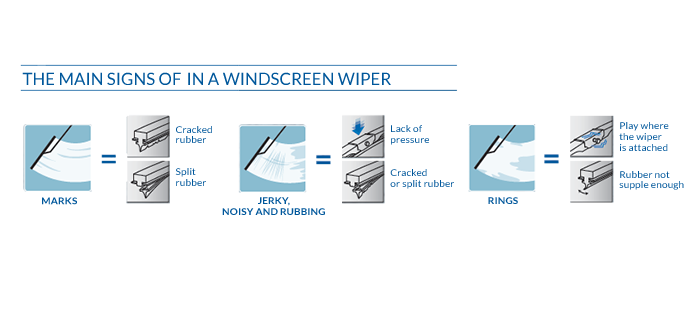

Designed with a natural material, rubber, these vital accessories to your daily work guarantee clean, silent wiping without leaving a single trace.KEY BENEFITS

New Holland recommends that you change your wiper blades at least once every 12 months to maintain optimum visibility.

-

REVITALISE YOUR CAB

SEATS

-

SEATS

Our seats are developed to minimise vibrations, and ensure greater comfort with:

- Specialised suspension to reduce the level of vibration

- Thick and comfortable seat cushions

- Enhanced lumbar support to protect the spine

- Absolute comfort thanks to a wide range of adjustments (extension of squib, angle of backrest)

Our VRS (Vibration Reduction System) seat absorbs 40% more vibration than classic pneumatic seats: thanks to patented and award-winning suspension, you gain in terms of comfort, efficiency and productivity.